Services

Hands-on forming support, training, and technology integration for container and tableware operations.

FORMING PROCESS TROUBLESHOOTING

Support typically includes:

Defect root cause analysis at the section level

Gob shape, temperature, and loading evaluation

Machine timing evaluation

Mold, plunger, and cooling balance review

Live trials and controlled adjustments

Operator coaching during real production

Equipment condition and setup review

I work directly on the forming floor to identify the real drivers behind defects, scrap, and inconsistency. The focus isn’t just fixing today’s problem, but understanding why it happened and how to prevent it from coming back on the next shift.

Identify the real causes behind defects and inefficiencies

CONTAINER I.S.

MACHINE SUPPORT

Support areas include:

Machine setup and timing logic

Section-to-section balance and repeatability

Startup, recovery, and changeover optimization

Shift handover consistency

Operator and technician coaching

I provide hands-on support for container I.S. machines with a focus on setup quality, section balance, and long-term process control. Whether you’re dealing with startup instability or chronic variation, the work centers on making the machine repeatable and predictable.

Consistency through discipline and understanding

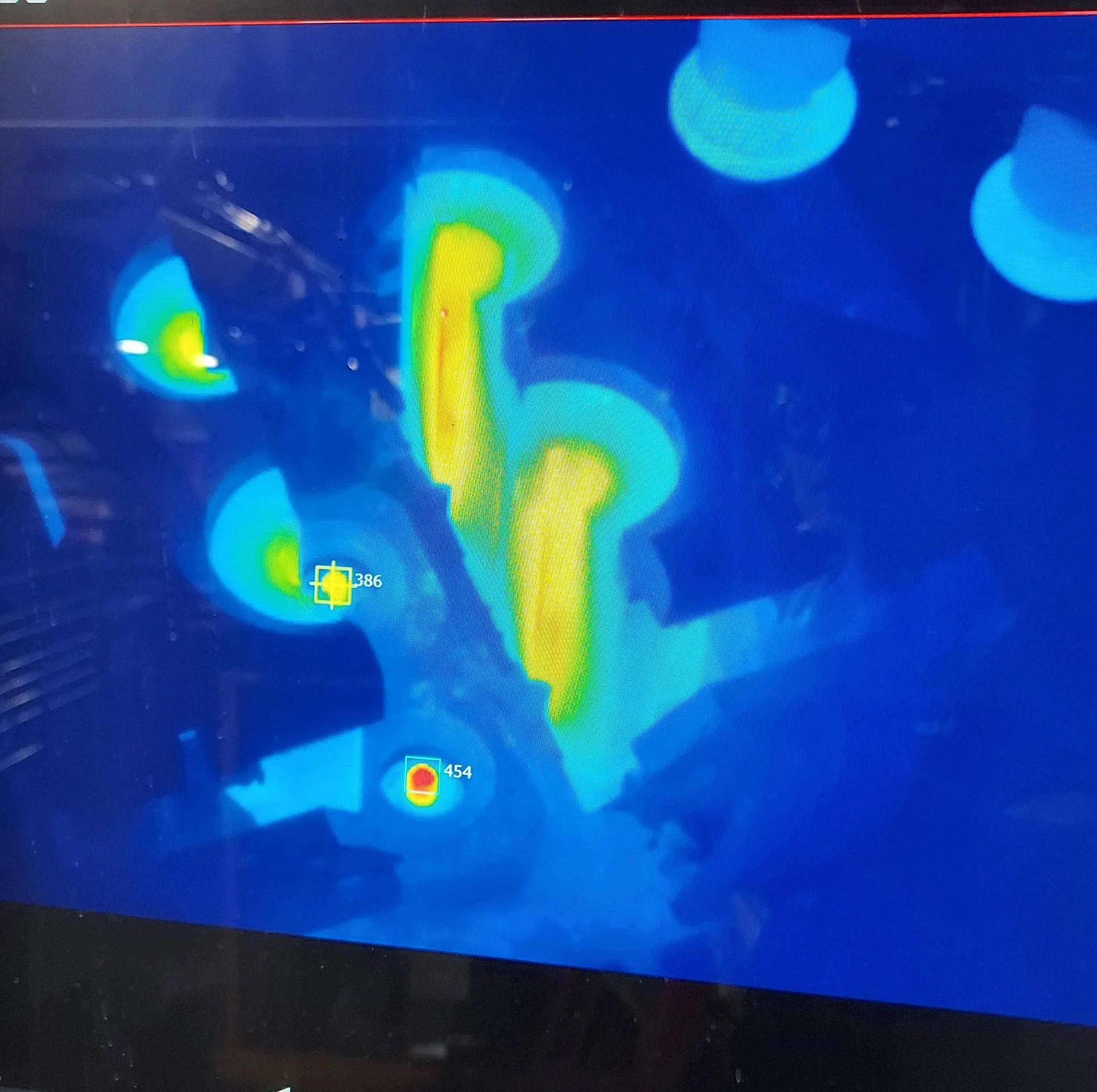

HOT END TECHNOLOGY IMPLEMENTATION

Advanced hot end inspection and monitoring systems can be powerful tools, but only when they’re implemented with the right expectations, setup, and training. I help bridge the gap between the technology and the reality of production.

Integrate advanced monitoring and inspection systems.

Support areas include:

Technology selection and readiness assessment

Installation and commissioning support

Integration with existing processes

Training operators, engineers, and supervisors

Turning inspection data into actions on the floor

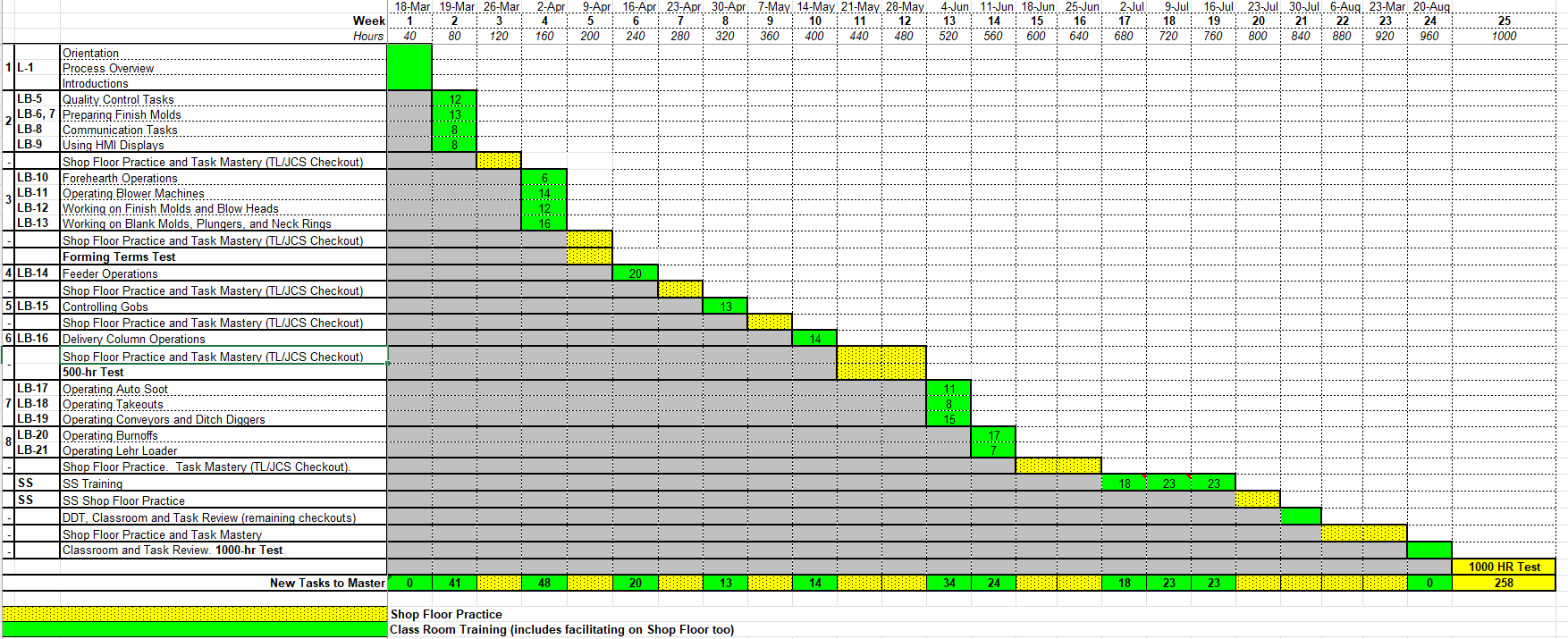

OPERATOR TRAINING

& DEVELOPMENT

Training support may include:

Apprentice training program development

Cross-training and skill development

Process understanding and defect awareness

Shift handover discipline

Supervisor and lead development

I focus on practical, floor-based and classroom training that helps operators understand not just what to adjust, but why adjustments work. I also work directly with forming trainers to develop training programs that fit the realities of their plant.

Build better teams with

real-world training.

TABLEWARE

FORMING SUPPORT

Support areas include:

Tumbler, stretch stemware, and 2-piece forming

Gob shaping and loading support

Press timing, pressure and temperature balance

Equipment review (tolerances, paste quality)

Burnoff setup and operation

Defect analysis

Process optimization for product quality

Pressed and blown tableware presents unique challenges that differ significantly from container production. I provide specialized support for operations where aesthetics, weight control, and forming precision matter just as much as throughput.

Decades of Tumbler, 2-Piece and stretch Stemware experience.

GLOBAL SUPPORT & CUSTOM SOLUTIONS

Support can include:

Short-term troubleshooting engagements

Multi-site support and technology rollouts

Remote advisory and follow-up support

On-site project execution

Forming evaluation and review

Acting as a technical bridge between plant teams, OEMs, and suppliers

Every plant operates within its own constraints, whether it’s equipment, staffing, budget, or timeline. I offer flexible support models designed to fit your specific situation rather than forcing a standard approach.

Flexible approach based

on your needs.

Let’s Talk About Your Forming Challenges

No generic proposals. No pressure.

Fully insured, including general liability and independent workers’ compensation coverage.