PUT.IT.BACK!

Let Me Get on My Forming Soapbox for a Minute…

One of my biggest pet peeves in forming is when changes are made, often silently, without fully understanding the issue or communicating what was done.

If you can’t explain WHY you made a change,

you probably shouldn’t be making it.

It usually goes like this; (drop a comment if you agree)

• A couple sections act up

• Someone adjusts a setting, glass temp, air pressure, whatever

• Suddenly, the entire machine is out of tune

• And no one knows what changed

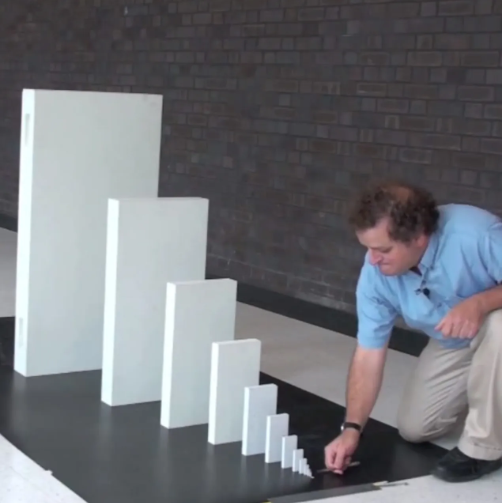

Every move in forming has a reaction.

That cause-and-effect relationship IS the job.

Even intentional changes come with a price elsewhere.

Before making a move, ask yourself:

Is this a section issue or a machine-wide issue?

How will this impact other stations down the line?

Do I understand the root cause, or am I just hoping for improvement?

And if it didn’t fix the problem?

PUT. IT. BACK.

Guesswork and ghost adjustments don’t help. They just throw everyone else off and bury the root cause even deeper.

FORMING SPECIALISTS!! This is for You! 👇

👉 As a Forming Specialist, I believe it’s my responsibility to share what I’m adjusting and why, not just to fix the issue, but to teach it. I may not be there the next time it occurs.

When others understand what was changed and what happened next, they become better operators. Make the learning part of the process. 👈

Glass forming is balance, not luck.

Control, not chaos.

Teach it. Don’t hide it.